Application Fields And Scope Of Chemical Pumps

Solid-Liquid Mixing Pump relies on the centrifugal principle to extract liquid materials. Chemical pumps made of special materials are suitable for extracting corrosive liquids from bottles, barrels, cylinders, pools or other containers.

1) Chemical pumps are widely used in chemical, petroleum, metallurgy, light industry, synthetic fiber, environmental protection, food, medicine and other departments. Chemical pumps have the advantages of stable and reliable performance, good sealing performance, beautiful appearance, and convenient use and maintenance. In order to improve product quality, reduce running, bubbling, dripping, leakage, prevent pollution, and improve the environment, they play a great role.

2) Chemical pumps are suitable for chemical, petroleum, metallurgy, power stations, food, pharmaceuticals, synthetic fibers and other departments to transport corrosive media at various temperatures or media with high physical and chemical properties.

3) Chemical pumps are used to pump clean water, containing abrasive substances, substances harmful to ordinary pump body materials, suspended substances, substances corrosive to stainless steel materials, and non-explosive substances;

4) Chemical pumps are also widely used for water supply; used for heating, air conditioning, cooling and circulation systems; Chemical pumps are used for civil and industrial purposes; used for fire fighting; used for irrigation; used for daily use and civil, industrial, gardening, irrigation purposes; used for rainwater storage projects; used in places where low noise is required; Chemical pumps are used for pressurization, suitable for conveying corrosive, explosive, and granular water or liquids; suitable for pipe network pressurization.

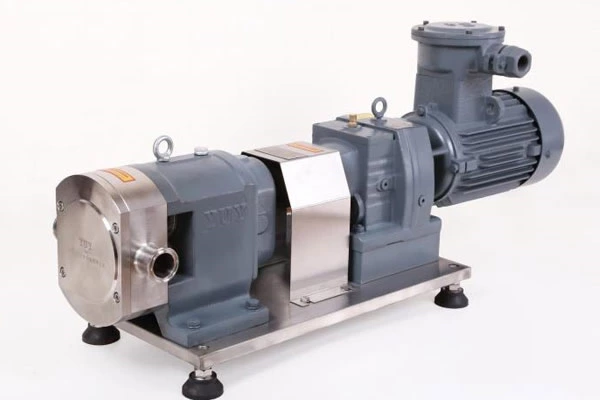

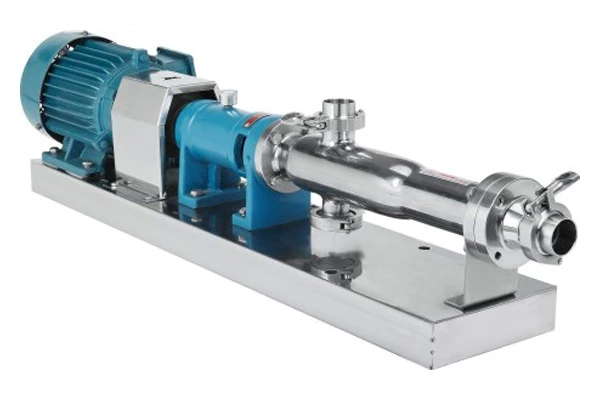

Chemical pump products mainly include: various glass fiber chemical pumps, corrosion-resistant plastic pumps, high-temperature chemical pumps, standardized chemical process pumps, magnetic drive pumps, etc.