Analysis Of The Reasons Why The Pump Does Not Produce Water After Starting

1. There is air in the water inlet pipe and pump body

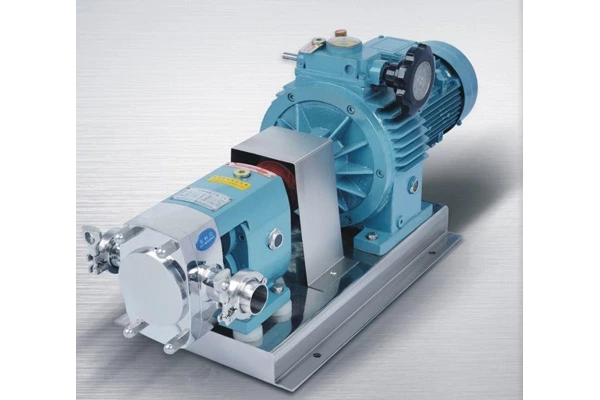

(1) Sanitary Rotary Lobe Pump was not filled with enough water before starting. Sometimes it seems that the water has overflowed from the vent hole, but the pump shaft has not been rotated to completely discharge the air, resulting in a small amount of air remaining in the water inlet pipe or pump body.

(2) The horizontal section of the water inlet pipe in contact with the water pump should have a downward slope of more than 0.5% against the direction of the water flow, and the end connected to the water pump inlet should be high, not completely horizontal. If it is tilted upward, air will remain in the water inlet pipe, reducing the vacuum in the water pipe and the water pump, affecting water absorption.

(3) The packing of the water pump has been worn out due to long-term use or the packing has been pressed too loose, causing a large amount of water to spray out from the gap between the packing and the pump shaft sleeve. As a result, external air enters the interior of the water pump through these gaps, affecting water extraction.

(4) The water inlet pipe has been submerged underwater for a long time, and the pipe wall has eroded and holes have appeared. After the water pump is working, the water level continues to drop. When these holes are exposed to the water surface, air enters the water inlet pipe through the holes.

(5) Cracks appear at the bend of the water inlet pipe, and there is a small gap at the connection between the water inlet pipe and the water pump, which may allow air to enter the water inlet pipe.

2. The speed of the water pump is too low

(1) Human factors. Some users arbitrarily install another motor to drive the original motor because the original motor is damaged, resulting in low flow, low head or even no water supply.

(2) Mechanical failure of the water pump itself. The impeller and pump shaft fastening nut is loose or the pump shaft is deformed and bent, causing the impeller to move more, directly rub against the pump body, or the bearing is damaged, which may reduce the speed of the water pump.

(3) The power machine is not properly maintained. The motor loses magnetism due to winding burnout. Changes in the number of winding turns, wire diameter, and wiring method during maintenance, or failure to completely eliminate the fault during maintenance will also cause the pump speed to change.

3. The suction range is too large

Some water sources are deep, and the outer terrain of some water sources is relatively flat, but the allowable suction range of the water pump is ignored, resulting in less water suction or no water suction at all (public account: pump pipe). It should be known that the vacuum that can be established at the water inlet of the water pump is limited. The suction range for vacuum is about 10 meters of water column height, and the water pump cannot establish the right vacuum. Moreover, if the vacuum is too large, it is easy to vaporize the water in the pump, which is not conducive to the operation of the water pump. Therefore, each centrifugal pump has its maximum allowable suction range, generally between 3-8.5 meters. When installing a water pump, you must not only seek convenience and simplicity.

4. The resistance loss of water flow in the inlet and outlet pipes is too large.

Some users have measured that although the vertical distance from the reservoir or water tower to the water source is slightly less than the pump head, the water volume is still small or no water can be lifted. The reason is often that the pipeline is too long, there are many bends in the water pipe, and the resistance loss of water flow in the pipeline is too large. The reason is often that the pipeline is too long, there are many bends in the water pipe, and the resistance loss of water flow in the pipeline is too large. Generally, the resistance of a 90-degree bend is greater than that of a 120-degree bend. The head loss for each 90-degree bend is about 0.5-1 meter, and the resistance of each 20-meter pipeline can cause a head loss of about 1 meter. In addition, some users also arbitrarily use the diameter of the inlet and outlet pipes of the water pump, which also has a certain impact on the head.

5. Influence of other factors

(1) The bottom valve cannot be opened. Usually it is because the water pump has been idle for too long, the bottom valve gasket is stuck, and the bottom valve without a gasket may rust.

(2) The filter screen of the bottom valve is blocked; or the filter screen is blocked by the sludge layer in the bottom valve.

(3) The impeller is severely worn. The impeller blades are worn after long-term use, affecting the performance of the water pump.

(4) Faults or blockages in the gate valve or check valve will cause a decrease in flow or even failure to pump water.

(5) Leakage in the outlet pipe will also affect the amount of water lifted.