Analysis Of Self-priming Non-clogging Sewage Pump

Sanitary Rotary Lobe Pump It is a new product successfully developed on the basis of repeated research on similar technologies at home and abroad. The pump integrates self-priming non-clogging sewage, adopts axial reflux and external mixing, and can be installed like an ordinary self-priming pump through the unique design of the pump body and impeller flow channel, without the need to install a bottom valve and irrigation water. It can also absorb and contain large-particle solids and long-fiber impurities in liquid, and can be widely used in urban sewage projects, river pond farming, light industry, papermaking, textiles, food, chemicals, power industry, fiber, slurry and mixed suspension. An ideal impurity pump.

Compared with similar domestic products, this pump has the characteristics of simple structure, good self-priming performance, strong sewage discharge capacity, high efficiency and energy saving, and convenient use and maintenance. It is a leader in the sewage pump series. . The highest technical performance indicators are in a leading position in China and have reached the international advanced level, with a broad application market and development prospects.

Product Use

Applicable to the discharge of seriously polluted wastewater from factories, sewage discharge stations in major residential areas, water systems of urban sewage treatment plants, drainage stations of civil air defense systems, water supply and water supply equipment plants, sewage discharge from hospitals and hotels, municipal engineering construction sites, mine supporting machines, rural biogas pools, farmland irrigation and other industries, and can also be used to transport sewage with sewage and dirt, clean water and weakly corrosive media.

Scope of Use

1. The ambient temperature is three 500℃, the medium temperature is 80℃, and the special requirements are up to 200℃.

2. The medium PH value of cast iron is 6.9, and the PH value of stainless steel is 2-13.

3. The medium weight does not exceed 1240 kg/m3

4. The self-priming height cannot exceed the specified value of 4.5-5.5 meters, and the length of the suction pipe is 10 meters.

5. The capacity of suspended particles is 60% of the pump diameter, and the fiber length is 5 times the pump diameter.

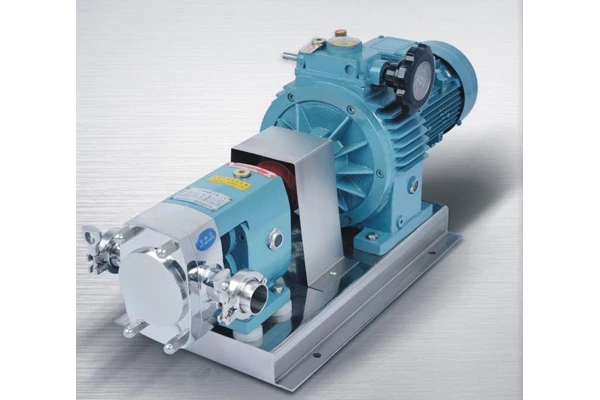

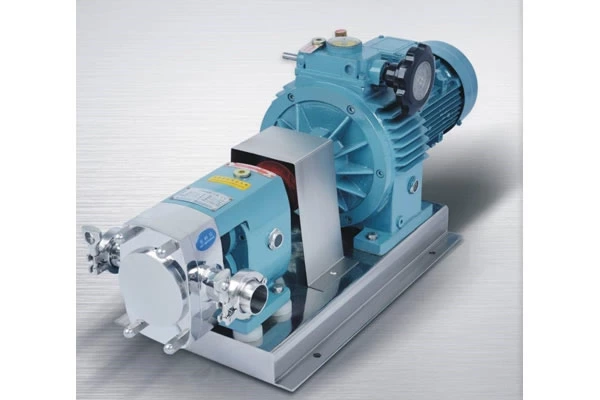

Structure and working principle

It is mainly composed of pump body, impeller, back cover, mechanical seal, pump shaft, bearing seat, air inlet valve, gas-liquid separation pipe, water supply valve, and air inlet and exhaust pipes. The structure of the pump is shown in the figure. Working principle of the pump: There is a liquid storage chamber on the pump body, which is connected to the pump working room through the upper return hole and the lower circulation hole to form an axial reflux external mixing system of the pump. After the pump stops working, a certain amount of liquid is stored in the pump chamber. When the pump is started, the liquid in the pump is thrown out by the impeller under the action of the impeller, and the liquid returns to the working room through the grille of the gas-liquid separation pipe, and the gas is discharged to the outside of the pump to form a certain degree of vacuum inside to achieve self-priming.

Preparation and operation before starting

1. Check whether the fasteners on the connecting parts such as the pump base, coupling, bearing box are loose? If loose, they should be fixed.

2. Is there any jam or abnormal sound when the coupling is turned manually?

3. Open the watering valve above the pump, add no less than two-thirds of the pump volume, and close the valve. No need to refill water after starting.

4. Connect the power supply and try to turn it. From the motor end, it rotates clockwise. (Reverse rotation is strictly prohibited)

5. Start working and observe whether the pump is running normally. If there is any abnormality, find out the cause and eliminate it.