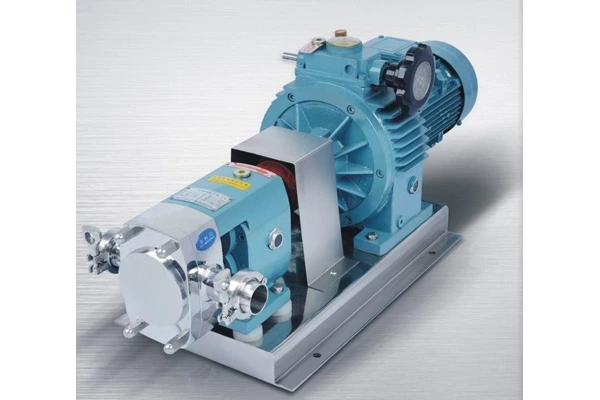

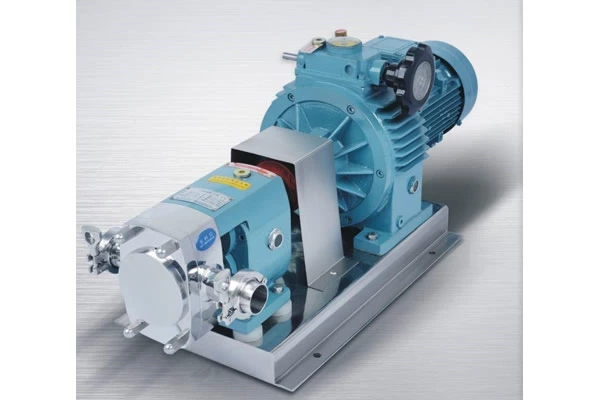

Advantages Of Sanitary Rotary Lobe Pumps And Requirements For Use Of Sanitary Rotary Lobe Pumps

Sanitary Rotary Lobe Pump is a combination of the performance parameters of the IS single-stage single-suction centrifugal pump and the performance parameters of the IS type single-stage single-suction centrifugal pump. It is cleverly designed based on the general vertical pump. At the same time, according to the use temperature, medium, etc., it is derived from the ISG type to be suitable for hot water, high-temperature corrosion-resistant chemical pumps and oil pumps. This series of products has the advantages of high efficiency and energy saving, low noise, reliable performance, etc., and meets the latest standards of the Ministry of Machinery. The products are designed and manufactured according to international standards. The ISG vertical pipeline centrifugal pump has a flow range of 1.5 to 1200m3/h and a head range of 8 to 150m. It is divided into more than 250 specifications such as basic type, expansion type, A, B, C cutting type, etc. According to different fluid media and temperatures, it is designed and manufactured into sanitary rotary cam pumps, IHG chemical pumps, YG oil pumps and IHGB explosion-proof chemical pumps with the same performance parameters.

The sanitary rotary cam pump should be selected according to the temperature medium

1.ISG vertical pipeline centrifugal pump is used to transport clean water and other liquids with physical and chemical properties similar to clean water. It is suitable for industrial and urban water supply and drainage, high-rise building pressurized water supply, garden sprinkler irrigation, fire pressurization, long-distance transportation, HVAC refrigeration cycle, bathroom and other cold and warm water circulation pressurization and equipment matching, and the use temperature T is less than 80℃.

2.IRG hot water pipeline centrifugal pump is suitable for metallurgy, chemical industry, textile, wood processing, papermaking, and hotels, bathrooms, hotels and other boilers. High-temperature hot water pressurized circulation and urban housing heating circulation pumps, the use temperature is below 120℃.

3.GRG high-temperature pipeline centrifugal pump is widely used in: energy, metallurgy, chemical industry, textile, papermaking, and hotels, bathrooms, hotels and other boilers. High-temperature hot water pressurized circulation and urban housing heating circulation pumps, the use temperature is below 240℃.

4. IHG vertical stainless steel pipeline centrifugal pump is used to transport liquids that do not contain solid particles, are corrosive, and have a viscosity similar to that of water. It is suitable for petroleum, chemical, metallurgy, electricity, papermaking, food, pharmaceutical and synthetic fiber sectors, and the operating temperature is -20℃ ~ 120℃.

5. YG pipeline explosion-proof oil pump is used to transport petroleum products such as gasoline, kerosene, diesel, etc. The temperature of the transported medium is -20℃ ~ + 120℃.

6. Sanitary rotary cam pump is suitable for transporting flammable chemical liquids.

7. ISGD, IRGD, GRGD, IHGH, YGD, IHGBD type vertical low-speed pipeline centrifugal pumps are suitable for occasions with very low environmental noise requirements and air conditioning circulation.

Unique advantages of sanitary rotary cam pumps

1. ISG type vertical pipeline centrifugal pump has a compact structure, small size and beautiful appearance. Its vertical structure has a low center of gravity and the center of gravity is at the center of the pump foot, which enhances the operating stability and life of the pump.

2. Easy to install. The inlet and outlet diameters are the same and on the same center line, and can be directly installed at any part of the pipeline like a valve. The motor can be placed outdoors with a rain cover. The ISG vertical pipeline centrifugal pump is equipped with a mounting foot to ensure stable installation of the pump:

3. Smooth operation, low noise, and high component concentricity. The motor uses low-noise bearings and is equipped with a non-stop refueling device. The pump impeller has excellent dynamic and static balance, operates without vibration, and improves the use environment.

4. No leakage. The shaft seal uses a corrosion-resistant and wear-resistant hard alloy mechanical seal, which solves the serious leakage problem of centrifugal pump packing, extends the service life, and ensures that the operating site is clean and tidy:

5. Easy maintenance. There is no need to disassemble the pipeline. Just remove the pump cover nut, take out the motor and transmission components for inspection and maintenance.

6. According to the on-site use conditions, the pump can be installed vertically, horizontally, and in multiple ways. According to the flow head requirements, the parallel and series methods are used to increase the required flow head.

What are the requirements for use?

1. The suction pressure of the sanitary rotary cam pump is ≤1.0Mpa, or the maximum working pressure of the pump system is ≤1.6Mpa, that is, the pump suction pressure + pump head is ≤1.6Mpa, and the pump static pressure test pressure is 2.5Mpa. Please indicate the system working pressure when ordering. When the working pressure of the pump system is greater than 1.6Mpa, it should be separately proposed when ordering. So that the flow-through parts and connecting parts of the pump can be made of cast steel materials during manufacturing.

2. The ambient temperature is <40℃, and the relative humidity is <95%.

3. The volume content of solid particles in the conveyed medium does not exceed 0.1% of the unit volume, and the particle size is <0.2mm.

Note: If the medium used is fine particles, please indicate it when ordering so that wear-resistant mechanical seals can be used.