8 Things To Consider When Selecting A Centrifugal Pump

1. Best Efficiency Point (BEP)

Before selecting a pump, you need to understand the optimal pump performance for your operation. One way to do this is to determine the Best Efficiency Point (BEP), which all pump manufacturers will provide. For example, a centrifugal pump should be operated between 50-120% of its BEP for best long-term performance.

2. Range of Conditions

Just as important as the BEP is understanding the full range of desired performance based on operating conditions. Flow, Net Positive Suction Head (NPSh), pressure ratings, and temperature are a few examples. The key is to understand what you need from your pump system before finding a device that will give you the results you need.

3. Margin of Error

It is difficult to determine the exact performance criteria you need before the pump is operating in the real world. You should be able to have a fairly accurate estimate to establish an acceptable range. Even so, be sure to meet your expectations in case you make a mistake. You may find a centrifugal pump that checks most boxes and is within the acceptable range. From here, you can dial it in with fine-tuning or customization.

4. Process Materials and Conditions

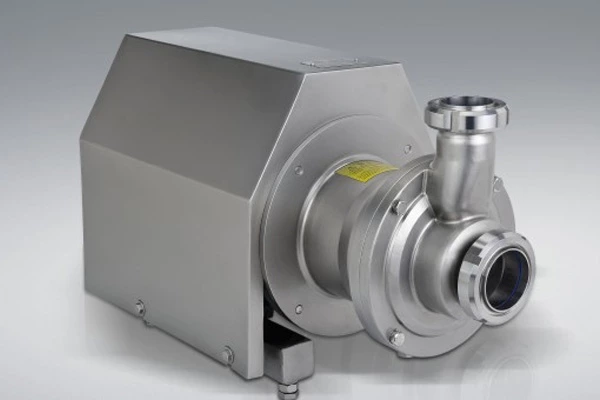

The different centrifugal pump applications are the reason for the small number of pump designs. In addition to the desired performance characteristics, you also need to understand the materials you are pumping. There are fluids, natural gas, liquids with solid particles, slurries, chemicals, and pure water. Some are acidic and corrosive and can damage seals and internal components, while others can cause plugging and cavitation. Choose the right pump and construction materials to handle the fluids and materials you are handling.

V. Environmental Conditions

Where you plan to install and operate your pump system is also an important factor. Consider whether it will operate outdoors, the atmospheric temperature and humidity it will be exposed to. Pump systems are designed to operate effectively and efficiently for their environment - understand the expectations for success.

VII. Safety

Safety is another key issue. You need a safe pump system to keep your operators safe and protect the environment. Many operations are subject to strict environmental regulations, and you want to avoid leaks to prevent contamination.

VIII. Maintenance

Based on the above operational factors, all Sanitary Centrifugal Pumps require routine maintenance - some more than others. Understand the maintenance requirements of your pump and make sure you get a unit that will ultimately provide more uptime rather than extended downtime for maintenance and repairs.