150 Technical Questions And Answers About Pumps To Help You Fully Understand Pumps

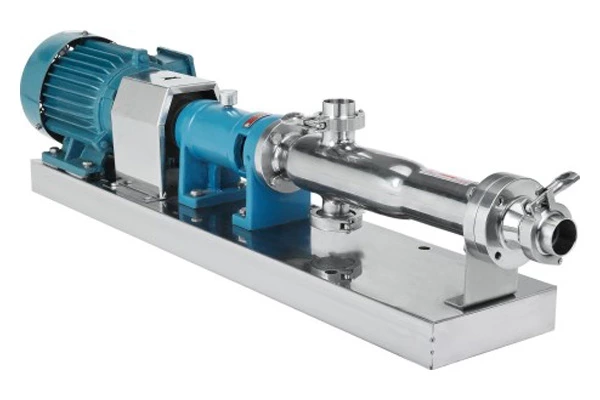

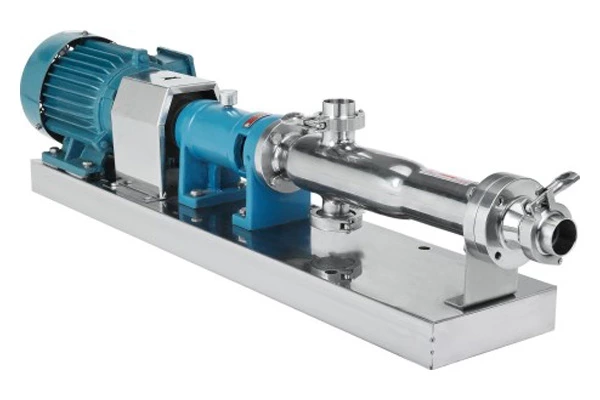

81. What are the "five fixed" rules for the management of Single Screw Pump types of lubricating oil?

Answer: For pumps, we should do the following: fixed point, fixed time, fixed quality, fixed quantity, fixed person, check and refuel to ensure the normal operation of the pump;

82. What is the basic principle of the importance of lubrication to machine pumps?

Answer: Lubricants can firmly attach to the friction surface of the machine parts to form an oil film. This oil film is strongly combined with the friction surface of the machine parts. The two lubricating surfaces are separated by lubricants, so that the friction of the machine parts becomes the friction of lubricant molecules, thereby reducing friction and wear and extending the service life of the machine parts.

83. What are the reasons for oil leakage in pumps lubricated with engine oil?

Answer: 1) The oil level is too high, and the inner hole of the bearing cover at both ends of the bearing box leaks oil; 2) Oil leakage at the static sealing point, such as oil leakage due to blockage of the oil drain wire; 3) Oil leakage between the bearing cover and the bearing joint surface;

84. What role does the lubricant play in the rotation of the bearing?

Answer: 1) Lubrication, 2) Cooling, 3) Washing, 4) Rust prevention, 5) Sealing, 6) Buffering and vibration reduction, 7) Anti-friction and wear;

85. What are the main properties of lubricating oil?

Answer: Acid value, viscosity, viscosity index, flash point, mechanical impurities, freezing point, residual carbon, ash.

86. How many methods are there to measure the clearance of radial sliding bearings? How to measure it with the shaft lifting method?

Answer: There are three commonly used methods: lead pressing method, shaft lifting method, and false shaft method. Shaft lifting method: Install a dial indicator near the shaft diameter of the bearing shell, and install a dial indicator on the top of the bearing shell for monitoring. Gently lift the shaft diameter until it contacts the upper shell, but do not make the upper shell move too much. At this time, the reading of the dial indicator on the shaft diameter minus the movement of the upper shell is the bearing clearance.

87. What are the faults of sliding bearings? How to deal with it?

Answer: Fault: bonding. Treatment measures: 1) Ensure the correct installation position and clearance requirements, 2) Ensure good lubrication of the rotor.

Fault: Fatigue rupture. Treatment measures: 1) Keep the bearing surface smooth, 2) Ensure good balance of the rotor.

Fault: Wear. Treatment measures: 1) Avoid insufficient lubrication, 2) Clean the lubrication system in time.

Fault: Scratches. Treatment measures: 1) Prevent instantaneous oil outage, 2) Avoid bumps during installation or removal.

Fault: Pulling. Treatment measures: Pay attention to the cleanliness of the oil circuit to prevent dirt from entering.

Fault: Cavitation. Treatment measures: 1) Increase the oil supply pressure, 2) Modify the shape of the bearing oil groove and oil groove, 3) Reduce the bearing clearance.

Fault: Electrocorrosion. Treatment measures: 1) Ensure that the insulation condition and protective devices of the machine are good, 2) Ensure that the machine is well grounded; 3) Check the shaft diameter. If electrocorrosion pits are generated on the shaft diameter, the shaft diameter should be polished to remove the pits.

88. What are the reasons for the bonding phenomenon of sliding bearings during use?

Answer: 1) Bearing overheating, 2) Excessive load, insufficient oil, 4) Improper operation or temperature control failure.

89. What are the reasons for abnormal noise when rolling bearings are running?

Answer: 1) Severe peeling of rolling elements or raceways, uneven surface. 2) Improper installation of bearing accessories, looseness or friction. 3) Iron filings or dirt in the bearing. 4) Lack of lubricant.

90. What are the radial clearances of rolling bearings?

Answer: 1) Original clearance: The clearance in the free state before the bearing is installed.

2) Fit clearance: The clearance after the bearing is installed on the shaft or in the hole. Its size is determined by the interference, and the fit clearance is smaller than the original clearance.

3) Working clearance: Some bearings, due to their structural characteristics, can have clearances that can be determined by adjusting the relative positions of the bearing rings during assembly or use, such as radial thrust ball bearings.