150 Technical Questions And Answers About Pumps To Help You Fully Understand Pumps

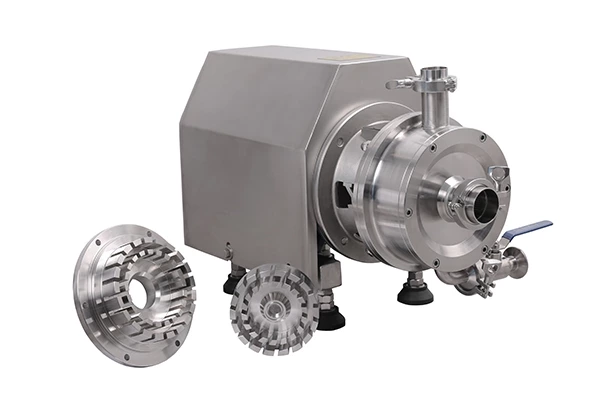

1. What is Emulsification Pump?

Answer: A pump is a machine that converts the mechanical energy of the prime mover into the energy of pumping liquid.

2. What is power?

Answer: The work done per unit time is called power.

3. What is effective power?

Excluding the energy loss and consumption of the machine itself, the actual power obtained by the liquid through the pump per unit time is called effective power.

4. What is shaft power?

Answer: The power transmitted to the pump shaft by the motor is called shaft power

5. Why is it said that the power transmitted to the pump by the motor is always greater than the effective power of the pump?

Answer: 1) When the centrifugal pump is in operation, part of the high-pressure liquid in the pump will flow back to the pump inlet, or even leak out of the pump, so some energy must be lost;

2) When the liquid flows through the impeller and pump casing, the changes in flow direction and speed, as well as the collision between fluids, also consume some energy;

3) The mechanical friction between the pump shaft and the bearing and shaft seal also consumes some energy; therefore, the power transmitted to the shaft by the motor is always greater than the effective power of the shaft.

6. What is the total efficiency of the pump?

Answer: The ratio of the effective power of the pump to the shaft power is the total efficiency of the pump.

7. What is the flow rate of the pump? What symbol is used to represent it?

Flow rate refers to the amount of liquid (volume or mass) flowing through a certain section of the pipeline per unit time. The flow rate of the pump is represented by "Q".

8. What is the head of the pump? What symbol is used to represent it?

Answer: The head refers to the increase in energy obtained by a unit weight of fluid. The head of the pump is represented by "H".

9. What are the characteristics of chemical pumps?

Answer: 1) Able to adapt to chemical process requirements;

2) Corrosion resistance;

3) High and low temperature resistance;

4) Wear resistance and erosion resistance;

5) Reliable operation;

6) No leakage or less leakage;

7) Able to transport critical liquids;

8) With anti-cavitation performance

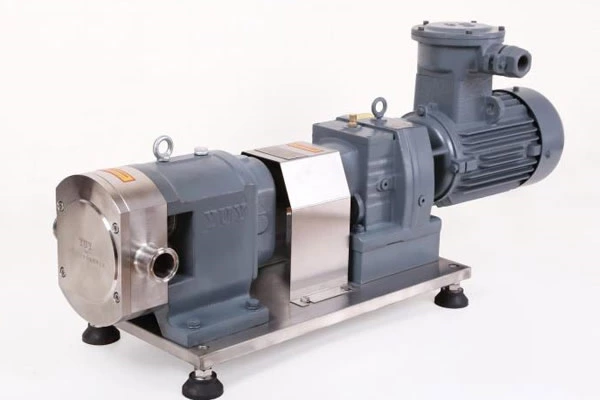

10. How many categories are commonly used mechanical pumps divided into according to their working principles?

Answer: 1) Vane pump. The pump shaft rotates to drive various impeller blades to give the liquid centrifugal force or axial force, and transport the liquid to the pipeline or container, such as centrifugal pumps, vortex pumps, mixed flow pumps, and axial flow pumps.

2) Positive displacement pumps. Pumps that use the continuous change of the volume of the pump cylinder to transport liquids, such as reciprocating pumps, piston pumps, gear pumps, and screw pumps;

3) Other types of pumps. Such as electromagnetic pumps that use electromagnetics to transport liquid conductors; pumps that use fluid energy to transport liquids, such as jet pumps, air lifts, etc.