14 Selection Criteria For Chemical Pump Materials

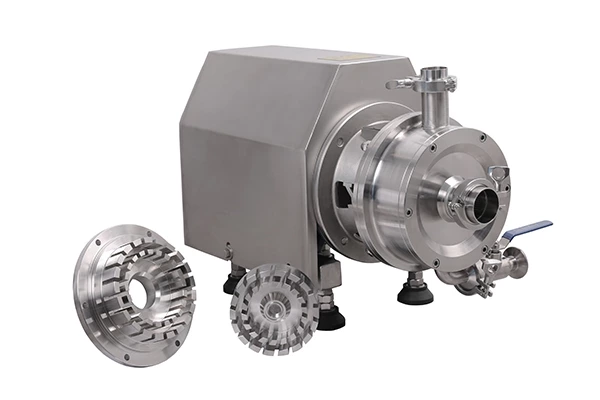

CIP Return Pump The selection of materials is crucial to the reliability of chemical pumps, especially for pumps used in refineries and chemical plants, which mostly work under flammable, explosive, highly corrosive, high temperature, low temperature and other process conditions. Therefore, my country and the United States have formulated specifications. Of course, the correct and economical selection of materials also requires rich experience and keen attention to the research and development of the latest materials at home and abroad.

14 selection criteria for chemical pump materials

1. The oxygen content and buffering effect of water should be considered when selecting materials.

2. Hydrocarbons, acids and acid slags with sewage corrosion exceeding 230°C may vary greatly. Recommended materials for various working conditions should be obtained. The material grades indicated in this table are satisfactory for many such working conditions, but they must also be verified. S-8 materials can also be considered for working temperatures below 95°C.

3. The materials selected for low temperature working conditions should meet the requirements of 5.12.4 and 5.12.1.6 in GB 3215-2007. The cast iron alloys ASTMA352, 1CB, 1C2 and 1C3 grades shown are for reference only. For wrought alloys, use equivalent materials.

4. Alloy materials based on aluminum, copper, aluminum copper and nickel can also be considered for low temperature conditions of -196℃.

5. If the corrosiveness of the material is low, S-4 grade materials can be used for service conditions of 231-370℃. Recommended materials for various working conditions should be obtained.

6 All welds should be stress relieved.

7. UNS N08007 or Ni-Cu alloy pump materials should be used.

8. For seawater, post-production water, formation water and brine working conditions, the buyer and seller should jointly agree on the structural materials most suitable for the intended service conditions.

The hydrocarbons, acids and acid slags may vary greatly. Recommended materials for various working conditions should be obtained. The material grades indicated in this table are satisfactory for many of these working conditions, but they must also be verified. For working temperatures below 95. C, S-8 materials can also be considered.

9. The materials selected for low temperature working conditions shall comply with the requirements of 5.12.4 and 5.12.1.6 of GB 3215-2007. The cast iron alloys ASTMA352, 1CB, 1C2 and 1C3 shown are for reference only. For forgeable alloys, use equivalent materials.

10. Alloy materials based on aluminum, copper, aluminum copper and nickel can also be considered for low temperature conditions of -196℃.

11. If the corrosiveness of the material is low, S-4 grade materials can be used for conditions of 231-370℃. Recommended materials for various working conditions should be obtained.

12. All welds should be stress relieved.

13. UNS N08007 or Ni-Cu alloy pump materials should be used.

14. For working conditions of seawater, post-production water, formation water and brine, the buyer and seller should jointly agree on the structural materials that best suit the intended conditions of use.